Blogs for Maintenance, Management and Reliability !!

Maintenance & Engineering

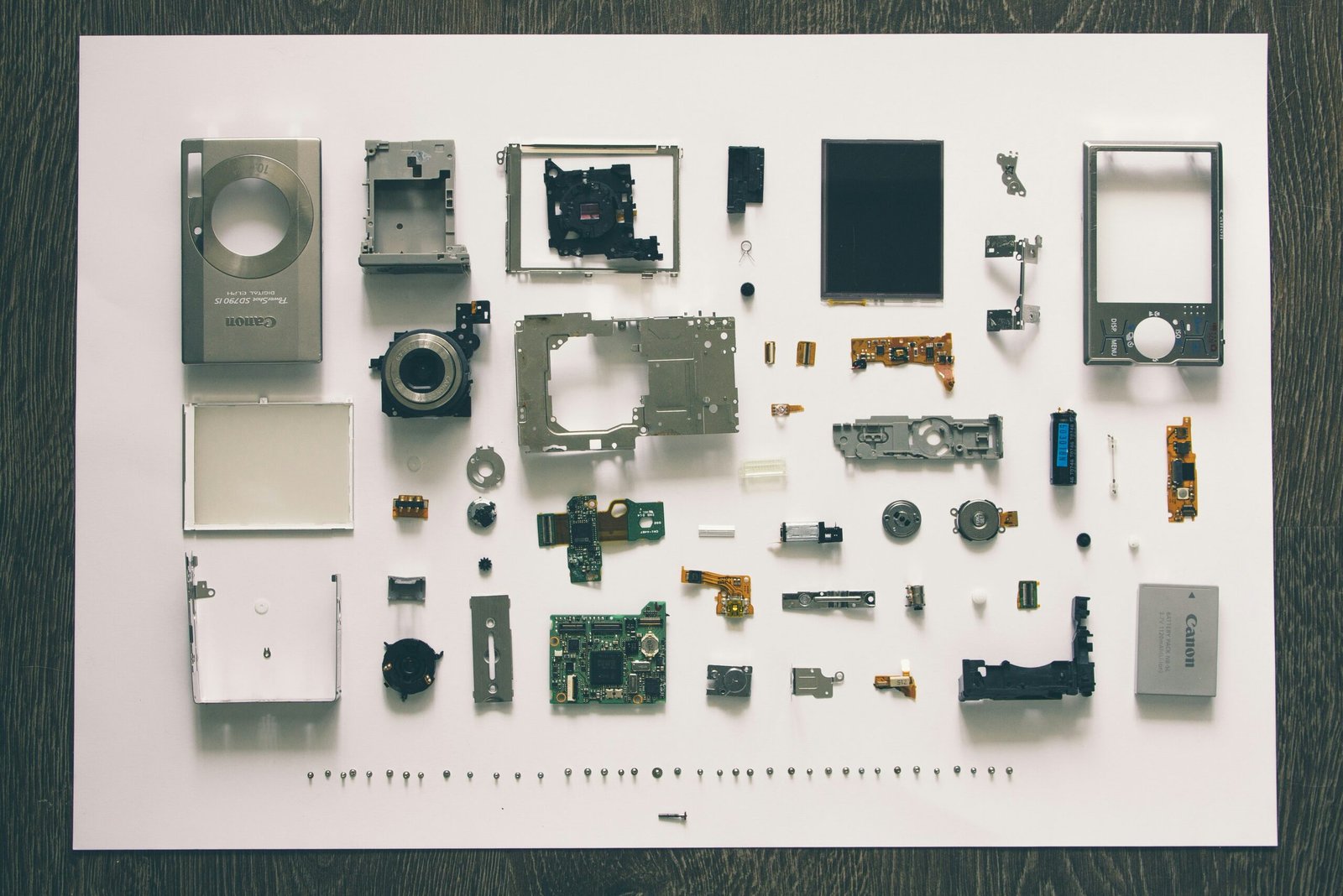

The Importance of Effective Spare Part Management Effective spare part management is a cornerstone of any robust maintenance strategy. At its core, it ensures that the right parts are available at the...

The Importance of Planning and scheduling in Maintenance The significance of planning in maintenance operations cannot be overstated. Effective planning delineates the critical distinction between...

Introduction to Computerised Maintenance Management Systems (CMMS) A Computerised Maintenance Management System (CMMS) is a software solution designed to streamline and automate maintenance management...

Manufacturing

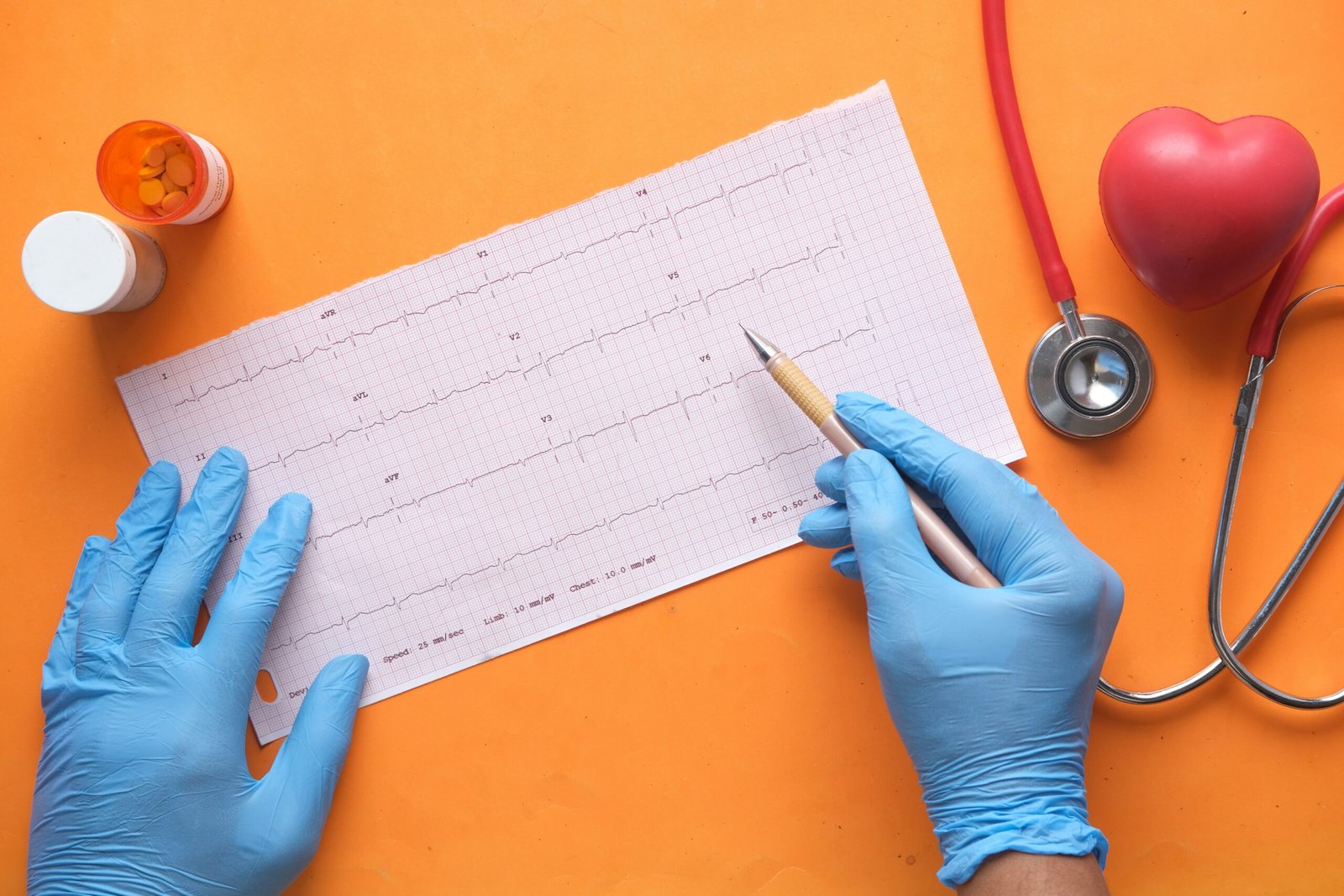

Introduction to FMEA Failure Modes and Effects Analysis (FMEA) is a structured approach employed to identify and evaluate potential failures in products, processes, or systems before they occur...

Introduction to Root Cause Analysis in Manufacturing Root Cause Analysis (RCA) is a systematic process used to identify the underlying origin of a problem, allowing companies to implement long-term...

What is Overall Equipment Effectiveness (OEE)? Overall Equipment Effectiveness (OEE) is a key performance indicator used in the manufacturing industry to assess the efficiency and productivity of...

Introduction to the 5S Program The 5S program is a systematic approach used in the manufacturing industry to organize and maintain workplaces for optimal efficiency and safety. Originating from Japan...

Management & Development

Introduction to Manufacturing Excellence In the ever-evolving landscape of global industry, achieving manufacturing excellence has emerged as a critical objective for businesses aiming to thrive. This...